MEFU Finishing Solution has been conducting in-depth research on laminating machines. In order to facilitate more people to operate laminating machines quickly, MEFU Finishing Solution has created a guide about MEFU laminating machines. The guide covers the types, sizes, lamination methods, and how to quickly use MEFU laminating machines, among other things.

In this guide, you can learn about the laminating machine that best suits your needs. In addition, we provide lamination technology training and comprehensive after-sales service, hoping to assist you.

What are the types of MEFU laminators?

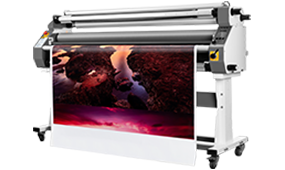

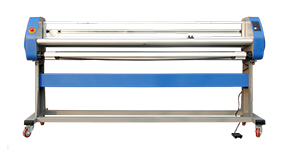

MEFU entry series laminating machines

MF1700-M1

MF1700-B5

MF1600-B7

MF1700-M1 PLUS

MF1700-M1 LITE

MF1700-B5 PRO

MEFU Premium Series laminating machines

MF1700-F1

MF1700-M5

MF1700-A1 PRO

MF1700-M1 PRO

MEFU Pro Series laminating machines

MF1700-F2

MF1700-F1 PLUS

MF1700-C3

Can I laminate different sizes?

Yes, you can! MEFU provides laminating machines with different sizes, and the maximum lamination width can reach 64 ''.

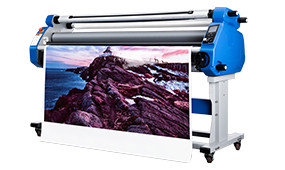

60 inch wide laminator

MF1700-B7 is a 1.52m/60in manual pneumatic lifting laminator. Suitable for most applications of signage and graphics with a width of up to 1520mm. 120mm silicone roller without glue, suitable for heavy-duty work.

64 inch wide laminator

The MF1700-C3 MEFU thermal assisted roll laminator is the best-selling 64 inch wide laminator with unparalleled performance and affordable price.

It is equipped with an ABS cover, which is more sturdy and aesthetically pleasing. Front and rear control panels, easy to check speed, temperature, and lamination statistics. Super machines can run at a speed of 20m/min in various media. Suitable for enterprises that want to add extra capacity and more features.

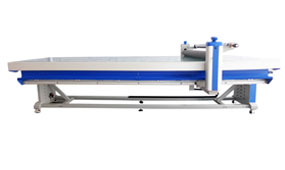

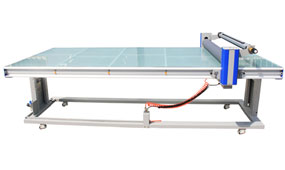

In addition, MEFU also offers PVC laminated cutting machines, which are ultra large laminated machines. Suitable for industries such as large-scale signage production and advertising production. This type of laminating machine has high processing efficiency and a wide range of applications.

Cold lamination vs hot lamination

The MEFU basic level MF1700-B5 is a best-selling cold layer press equipped with pneumatic lifting, which provides more uniform pressure and easier operation compared to traditional manual machines. It is suitable for most signage and graphic applications with a width of 1630mm/64 inches. The classic manual crank can easily adjust the running speed during the lamination process.

The industrial grade fully automatic laminating machine MF1700-F2 is very suitable for most signage and graphic applications. The double heating roller with a maximum temperature of 120 degrees Celsius can not only be laminated but also be installed and packaged up to 1630 millimeters.

The heating roller adopts a built-in oil heating system, which has a high degree of machine automation, accurate edge matching, convenient operation, and improved work efficiency. It is the most ideal equipment for hot lamination. In addition, its fully adjustable tungsten blade can cut most materials and has a service life of over 15000 meters.

.jpg)

How to use MEFU lamination?

The MF1700 series laminating machine can use low-temperature or high-temperature cold adhesives or hot laminating films for lamination, making it an ideal commercial laminating solution. The thermal assistance of cold adhesive film has better smoothness during cold lamination or installation process.

Lamination is an extremely delicate and technical task, and beginners should train well. The following are the basic operating steps provided by MEFU:

1.Preheating: Through thermal assisted cold lamination, there are absolutely no bubbles between 40 ℃ and 50 ℃, and the temperature during the hot lamination process depends on your medium and hot film.

2.Tear off the inner lining: Pull out some thin film through the drum and then fix it onto the finished roll (only suitable for beginners).

3.Fixation: Fix the printed material and secure it on the workbench.

4.Adjusting tension: If the film does not have appropriate tension, please turn the damping knob clockwise to obtain tension.

5.Adjust speed: Rotate the speed button clockwise to the appropriate speed. The faster the speed, the more heat dissipation, so please choose the appropriate lamination speed and temperature.

How to choose a suitable laminating machine?

How to choose a suitable laminating machine?

There are many factors to consider when choosing a suitable laminating machine, so please carefully consider your own needs before making a choice.

1. Lamination size and thickness: Determine the maximum size and thickness you need to laminate.

2. Lamination speed: Choose the appropriate laminating machine speed according to your needs. If you need a large amount of lamination, choosing a faster machine may be more suitable.

3. Lamination function: Some laminating machines have additional functions, such as hot lamination and cold lamination, as well as single-sided or double-sided lamination. Choose a machine with corresponding functions according to your needs.

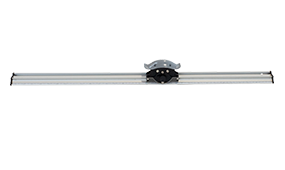

In addition to laminating machines, MEFU is also a supplier of flatbed applicators and cutting machines. We focus on finishing Solutions and are pleased to provide you with comprehensive services. If you have more information, please consult us!

.png)

.jpg)