64″ Automatic Industrial Laminator With Advanced Laser Device

MEFU has been innovating to bring better laminating processes to customers. To improve precision and reliability, an MEFU laminate machine with laser positioning and cutting function has been developed.

A laser sensor is an instrument that utilizes a laser to determine the distance to a target accurately. As one of the commonly used sensors in the field of industrial automation, laser sensors are used in a wide variety of applications, including various industries such as machinery manufacturing, automation control, measurement, and monitoring. In the field of machine building, it has been widely used for navigation, localization, quality inspection, and parts inspection.

MEFU has been innovating to bring better laminating processes to customers. To improve precision and reliability, an MEFU laminate machine with laser positioning and cutting function has been developed.

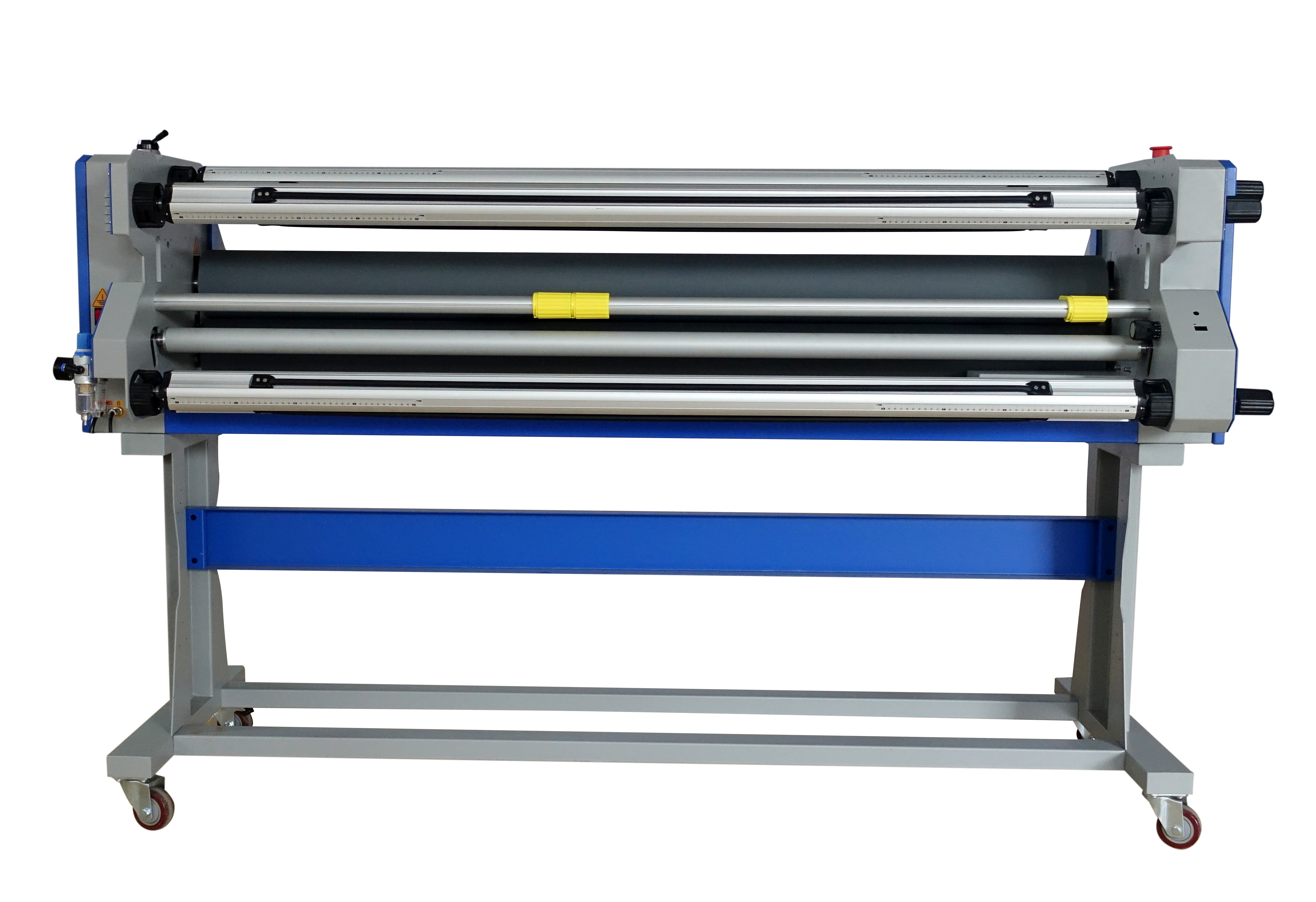

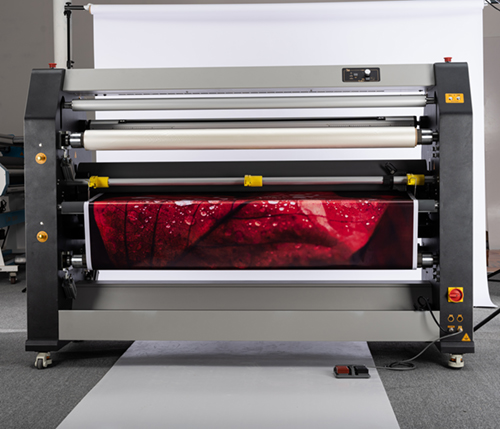

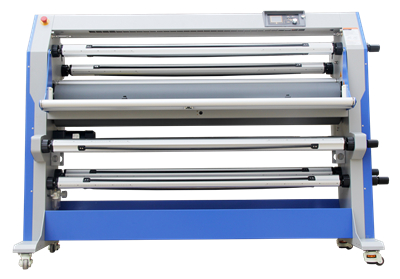

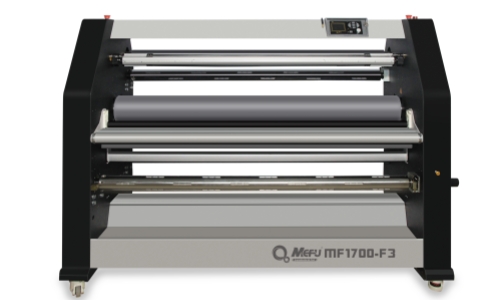

The MF1700-F3 fully automatic industrial-grade laminator is the first choice for heavy-duty industries.

Firstly equipped with high quality 150mm diameter large silicon rollers for heavy duty work. Secondly, the Smart Pro system allows easy checking of speed, temperature, and lamination statistics on the front and rear control panels. Finally advanced laser positioning and cutting equipment for automatic tracking and correction during lamination and cutting with high accuracy and low error.

1. Swing in & out air shafts

Swing in and out air shafts, easy for heavy rolls loading and unloading

Air tension button for locked shafts and air-filled, convenient for us

2. Front Panel

Speed, temp, and lamination statistic: easy to check figures of set temp, real temp, and button speed, as well as find your lamination records in 30 days

Auto Slow-down and Stop when media come to an end

Alarming for stop, safety protection, and overloaded media

Dual foot-pedal (one for up and down roller, the other for lamination)

Date and time display

3. Rear Panel

Automatic cutting correction, active by button on rear display, automatic correction, and track cutters, more precise and have good finishes

Speed statistics, show button speed, which is convenient for adjusting machine speed

Cutting active by button, easy to use

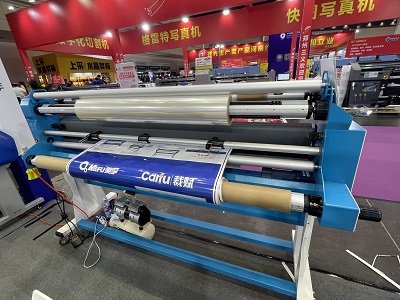

4. Laser positioning device

Vertical cutting correction

Auto track and correction during laminating and cutting

5. Safety vertical cutters

Equipped with 3 trimmer holders, 2 Single and 1 Double central blade

Upgraded with two paddles on 2 single trimmer holders

Durable tungsten steel blades can cut common media with a lifetime of over 15000m

If you want to learn more, please contact us!