Air Shafts Design For Industrial Laminating Machine

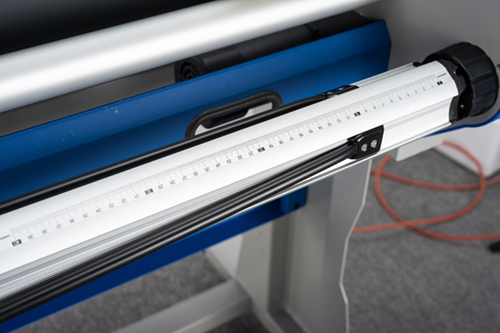

The design of air shafts relies heavily on pneumatic technology and mechanical construction. The pneumatic cylinder drives the air shaft to oscillate through compressed air, and the connected oscillating mechanism makes it move within a certain range. During the laminating process, the air pressure and swing angle can be adjusted by the control system to achieve precise loading and unloading of materials.

The design of air shafts relies heavily on pneumatic technology and mechanical construction. The pneumatic cylinder drives the air shaft to oscillate through compressed air, and the connected oscillating mechanism makes it move within a certain range. During the laminating process, the air pressure and swing angle can be adjusted by the control system to achieve precise loading and unloading of materials.

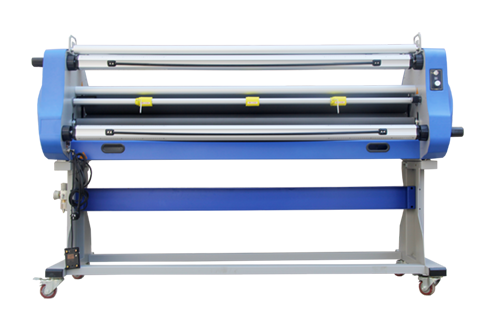

Advantages Of Air Shafts Design

1.The convenience of swinging in and out: The design allows the air shaft to swing in and out easily when needed, making it convenient for users to load and unload heavy rolls of material.

2.Reliability in loading and unloading of heavy rolls: the oscillating function of the air shaft is particularly suitable for handling heavier rolls, making the loading and unloading process safer and more reliable.

3.Suitability for different materials: the machine is equipped with an air pressure button, which makes it easy to inflate and deflate rolls of different diameters.

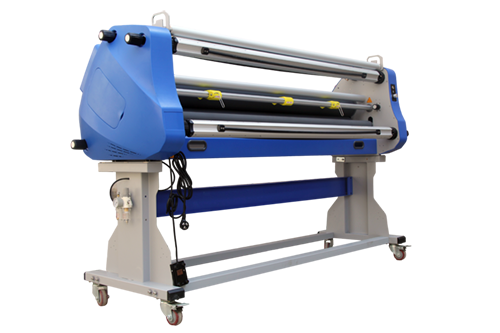

The air shaft swing function is particularly helpful in handling the following types of materials.

1.heavy roll materials: such as paper, plastic film, metal foil, etc. These materials are usually heavy and can be easily loaded and unloaded by swinging the air shaft, which makes the operation less difficult.

2.large diameter rolls: such as large rolls of plastic or textiles, the oscillating function of the air shaft makes it possible to handle them smoothly even when space is limited.

3.fragile materials: such as film or scratchy surfaces, the oscillating air shaft reduces friction and damage to the material during loading and unloading.

4.multi-layer materials: such as composite materials or multi-layer films, the oscillation function can help to keep the materials neat and stable during loading and unloading, preventing chaos.

5.Frequent material changeovers: In production environments where different rolls need to be changed quickly, the air shafts’ oscillating feature can increase efficiency and reduce downtime.

Air shafts are designed to dramatically increase the efficiency and safety of handling a wide range of roll types.