Cold or hot lamination? Influence of laminating temperature on lamination effect

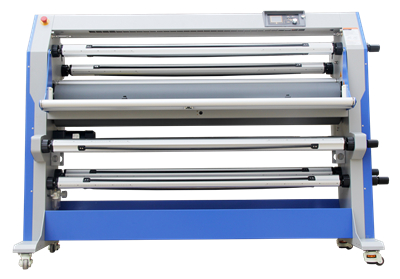

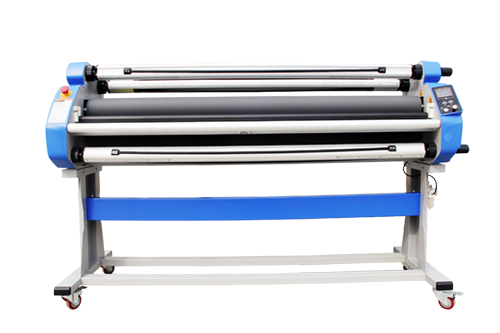

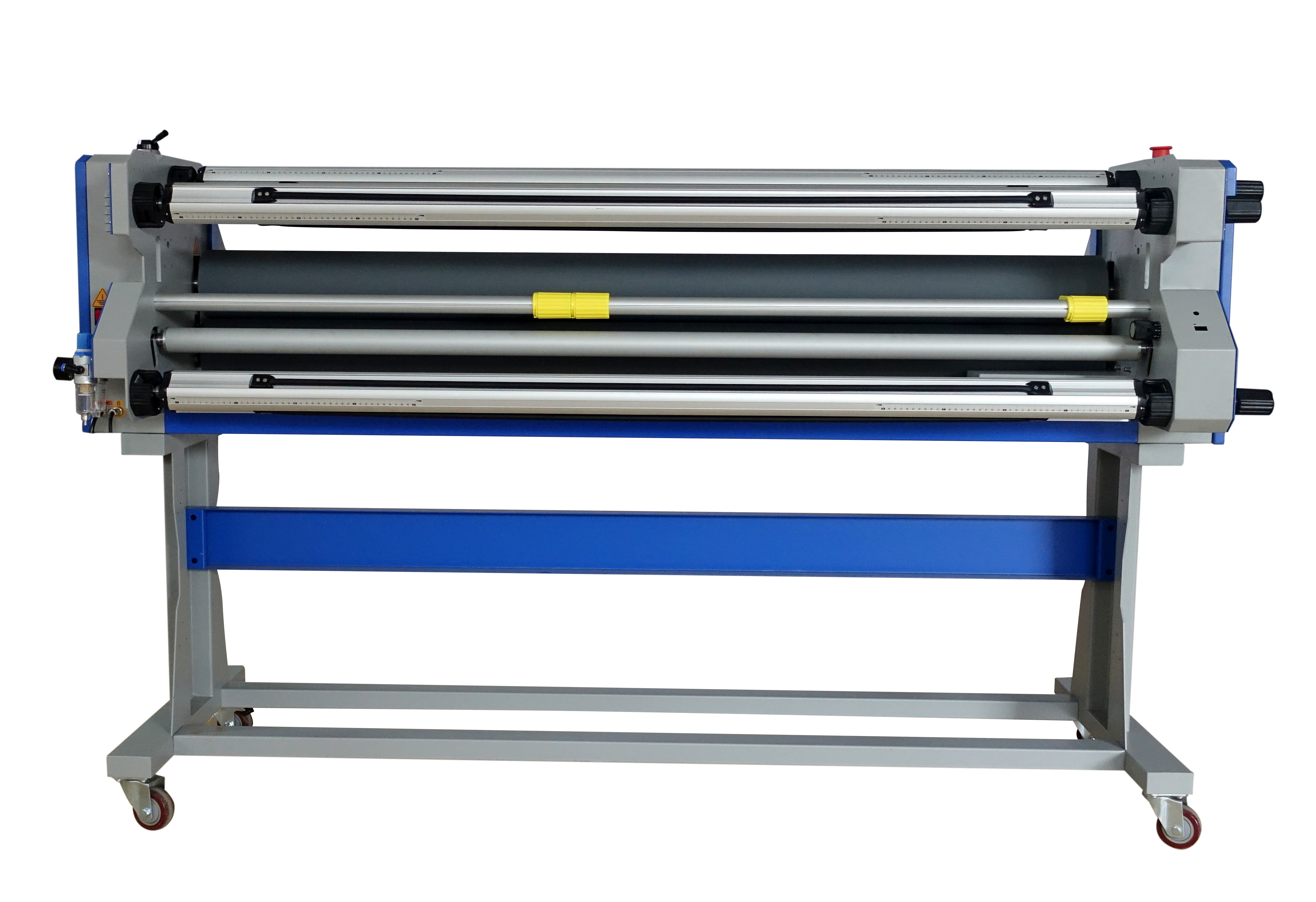

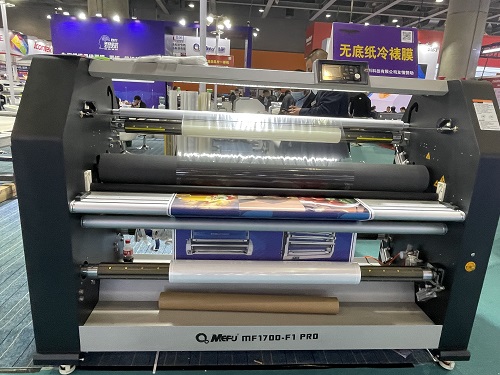

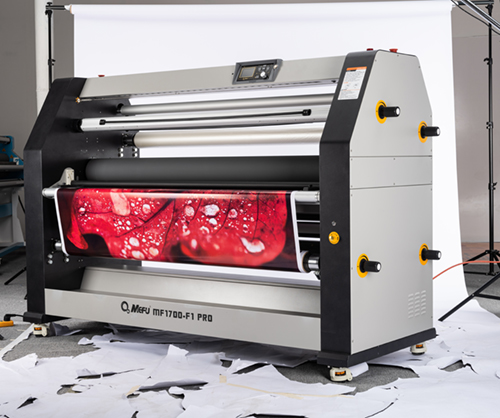

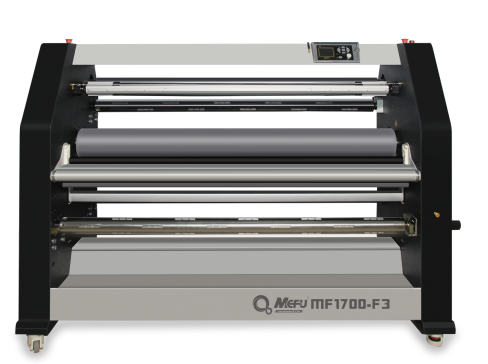

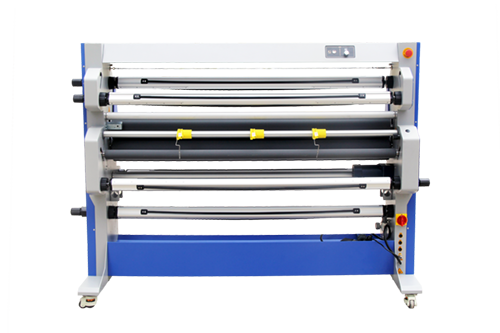

The laminator for both cold and hot lamination – the MEFU Roller Laminator, the best laminator for laminating in 2024.

The laminator for both cold and hot lamination – the MEFU Roller Laminator, the best laminator for laminating in 2024. I’m sure you have many questions about roll laminators.

What is the difference between cold and hot lamination in the process?

- Temperature control method:

– Cold lamination: Cold lamination machine uses normal or low temperature in the process, no additional heating is needed, and it mainly relies on mechanical pressure to complete the material molding.

– Hot Lamination: Hot lamination needs to be heated to a certain temperature while being pressurized to induce material flow and bonding to form the desired molding.

- Applicable materials:

– Cold Laminator: Cold laminator adopts high-quality rubber rollers made by unique technology, which makes the laminating smoother. A cold laminating machine is widely used in modern weddings, art photography, computerized airbrushing, and the laminating work of calligraphy and painting, posters, advertising pictures, effect drawings, documents, and materials.

– Hot laminator: The machine completes the laminating and mounting of boards and pictures with high temperature and high pressure. Compared with the cold laminating machine, the cost is lower, but the effect is better, and the surface of the mounted products is preserved for a longer time. Suitable for all flat boards and rolled media web. The replacement of the corresponding film consumables can be a variety of glass decals, acrylic sheets, or PVC boards.

- Molding effect:

– Cold lamination: the molding process is relatively fast because it does not need high-temperature heating, but it may affect the fluidity and adhesion of the material.

– Hot lamination: the fluidity and adhesion of the material can be better controlled by heating, to get better molding effect and strength.

What is the choice between cold laminating and hot laminating machines?

The choice between a cold or hot laminator depends on your specific needs and material properties. If you need to process temperature-sensitive materials or have high processing costs, consider choosing a cold laminator. Cold laminators are easy to operate, inexpensive, and suitable for materials that do not require high-temperature processing.

If you have high demands on the strength, wear resistance, and appearance quality of your products, you can consider choosing a hot laminator. Thermal laminators can treat materials at high temperatures and pressures to improve the quality and performance of your products, making them ideal for applications where product quality is critical.

Why choose the MEFU Roll laminator?

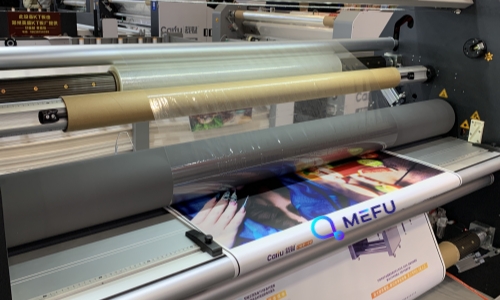

The MEFU pro series of laminators can be cold or hot-pressed, and this series of laminators is MEFU’s best seller. In addition to the advantages of cold lamination and hot lamination, the MEFU 1700 also features cutting while laminating, making it the most cost-effective laminator available.

Of course, MEFU’s range of cutting machines is constantly being innovated, and MEFU’s automatic cutting machines are now ideal for cutting both flexible and rigid materials.