Common cold lamination problems – wrinkles and solutions

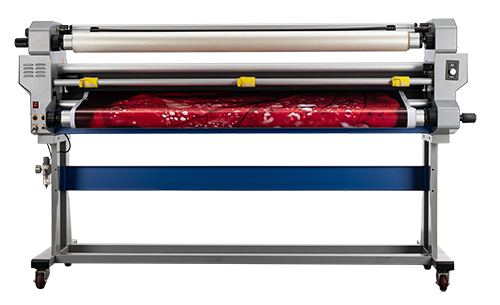

Laminators play a key role in the laminating process. The use of a low-temperature cold laminator can be effective in preventing wrinkles. Although cold laminating films rely primarily on cold bonding, in some cases, proper heating can improve adhesive bonding and reduce wrinkling.

Cold lamination film relies on the adhesive effect of glue to apply pressure through the laminator for lamination, which will not damage the original paper or printed pattern. It is widely used in the printing industry. However, compared with hot lamination, cold lamination film has lower adhesiveness and is prone to wrinkling.

Reasons for cold lamination wrinkles:

1.The tension on both sides of the cold lamination film or printed matter is inconsistent, causing the picture to be uneven and causing the lamination film to wrinkle.

2.Uneven lamination speed or excessive operating tension can cause the lamination film to wrinkle.

3.The laminating machine is of poor quality or fails, causing the laminating film to wrinkle.

4.The width of the film is greater than the width of the printed matter, and the excess film edge shrinks and wrinkles appear.

Solutions to wrinkles in cold lamination film:

1.Adjust the tension: Adjust the tension setting of the machine to achieve consistent tension on both sides of the cold lamination film and the printed matter.

2.Control the lamination speed: Let the laminator work for some time before putting in the film and printed materials, and then laminate after maintaining a stable speed.

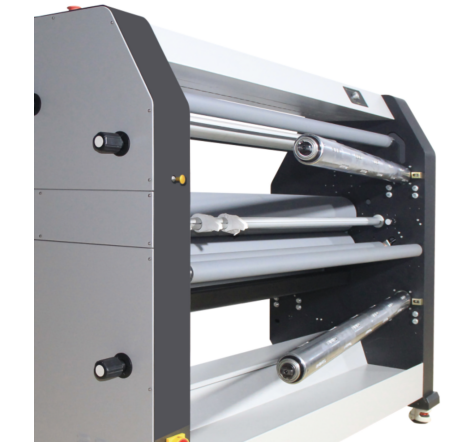

3.Check the equipment regularly: Check the working status of the laminating machine regularly to ensure the normal operation of the equipment and avoid uneven tension caused by equipment failure.

4.The width of the film matches the printed materials: Make sure that the width of the cold laminating film matches the printed materials to avoid the excess part of the film shrinking and causing wrinkles. The paper width is preferably greater than the width of the film so that there is no excess film edge and the quality is improved.

5.Use high-quality materials: Choose high-quality cold laminating film. High-quality film is not prone to wrinkling during bonding.

6.Improve operating skills: Operating skills are very important during lamination, which can effectively avoid wrinkles.

Laminators play a key role in the laminating process. The use of a low-temperature cold laminator can be effective in preventing wrinkles. Although cold laminating films rely primarily on cold bonding, in some cases, proper heating can improve adhesive bonding and reduce wrinkling.