How Can a High Speed Laminator Achieve Precise Lamination?

The key to the precision of the MF1700-F1 PLUS is its laser positioning technology. This system ensures exact alignment during lamination by continuously adjusting the material position in real time, preventing errors that can occur at high speeds.

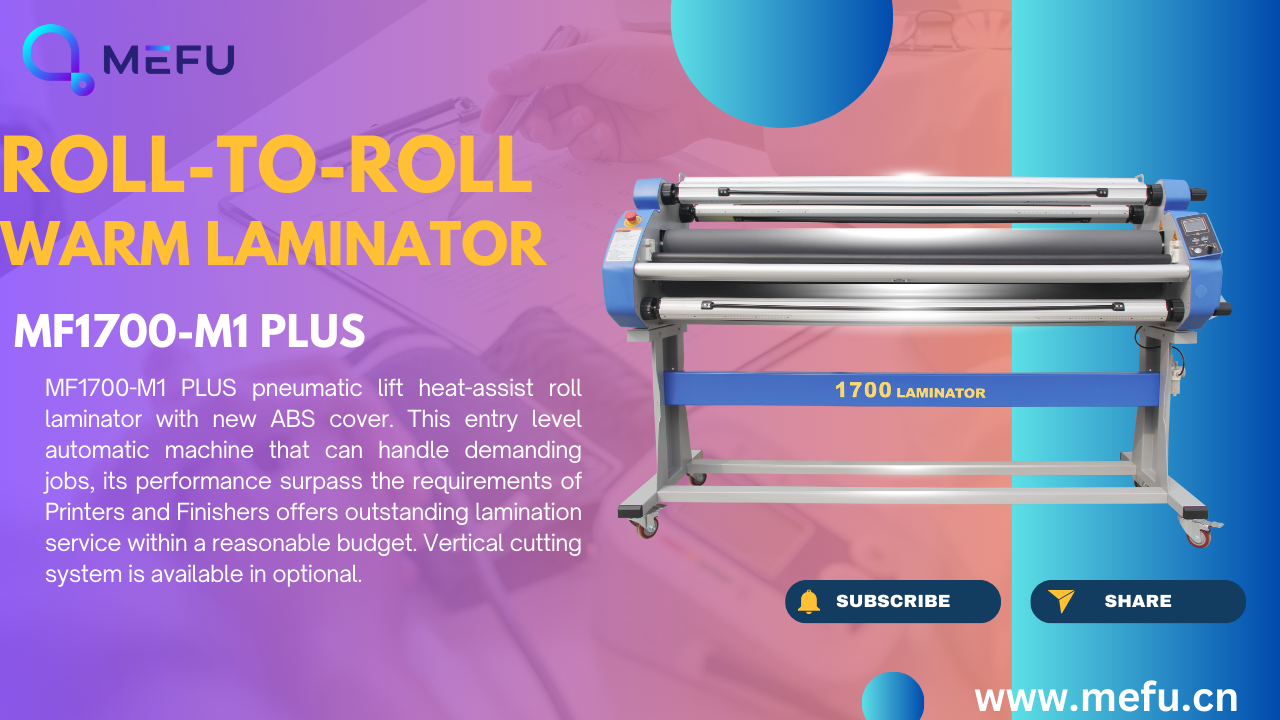

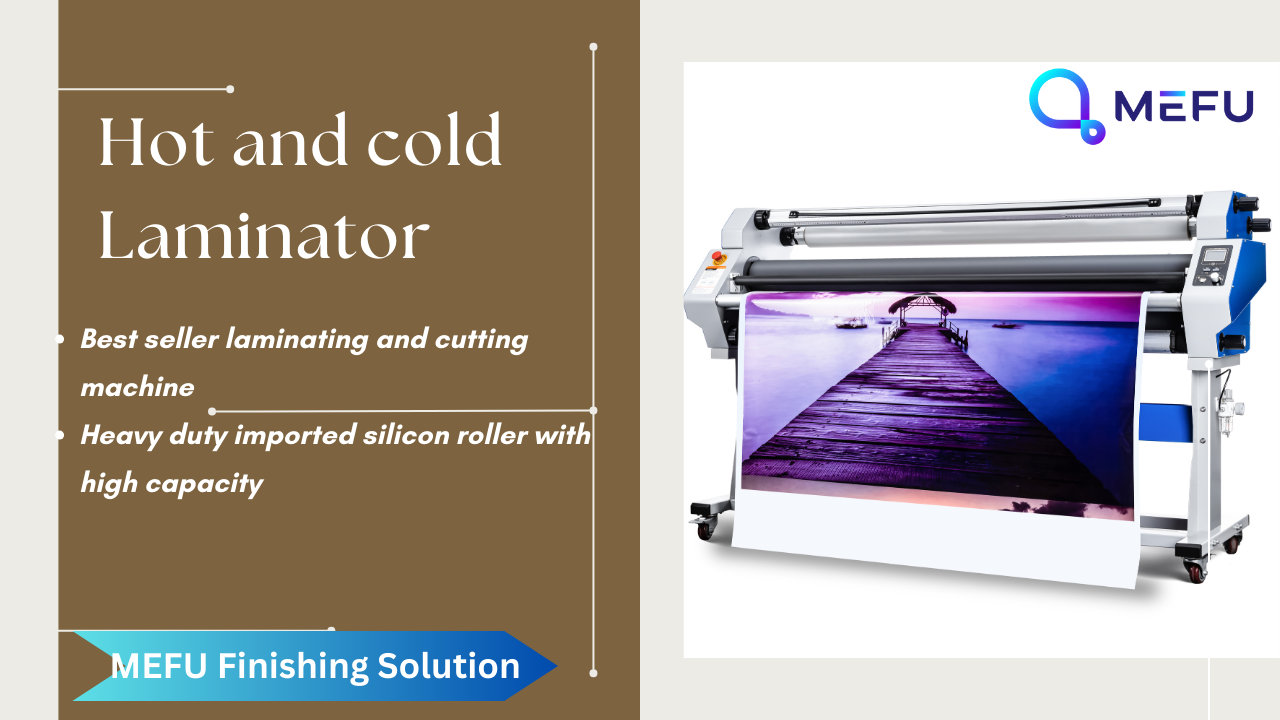

With the increasing demand for high-speed lamination, manufacturers are constantly innovating to meet the industry’s need for speed and precision. MEFU’s MF1700-F1 PLUS stands out with its cutting-edge features, offering an impressive laminating speed of 50 meters per minute while maintaining unparalleled precision.

So, how does a high speed laminator like the MF1700-F1 PLUS achieve such precise lamination?

1.Advanced Laser Positioning System

The key to the precision of the MF1700-F1 PLUS is its laser positioning technology. This system ensures exact alignment during lamination by continuously adjusting the material position in real time, preventing errors that can occur at high speeds.

2.High Speed Die CuttingSystem

The MF1700-F1 PLUS also serves as a high-speed die cutting machine with an advanced cutting device. This feature allows for highly accurate cuts, reducing the need for post-lamination trimming. The cutting mechanism and the lamination system create a seamless workflow where materials are laminated and cut precisely in one go.

3.Maintaining Quality At High Speed

Even at impressive speed, the machine maintains consistent quality through optimized temperature control and precise pressure rollers, ensuring every project is perfectly laminated without bubbles or wrinkles.

For businesses seeking to optimize production without sacrificing quality, the MF1700-F1 PLUS is the solution. Invest in precision and efficiency—upgrade your workflow today with the power of advanced high speed lamination technology!