How Do i Laminate My Thermal Transfer Printing?

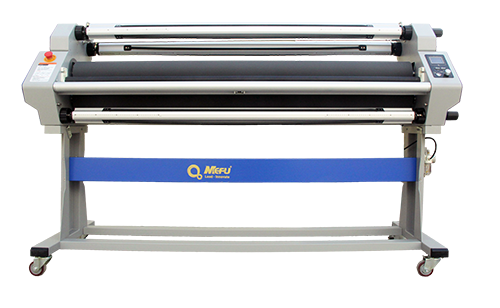

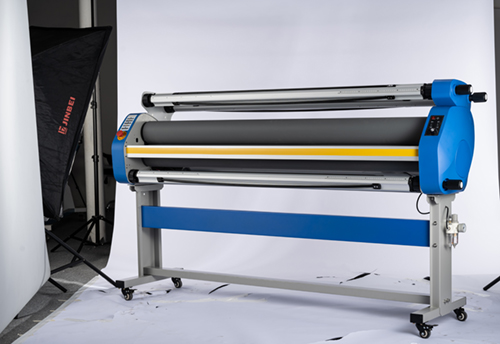

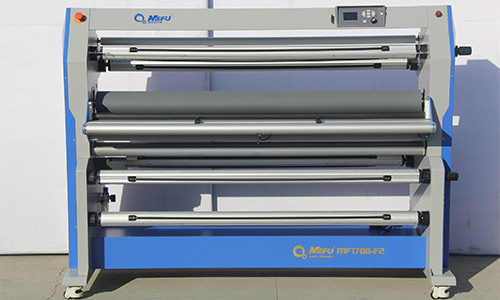

The MF1700-F2 with top heating is ideally suited for laminating most thermal materials. The dual heating rollers with a maximum temperature of 120°C allow lamination and mounting.

Due to the special characteristics of thermal transfer print, if they are not protected, they are more susceptible to moisture, color fading, and other damage caused by external factors such as water vapor and ultraviolet rays. Thermal transfer prints require heat lamination, and it is necessary to heat the laminator with a heated roller to realize the lamination between the thermal material and the film.

The MF1700-F2 with top heating is ideally suited for laminating most thermal materials. The dual heating rollers with a maximum temperature of 120°C allow lamination and mounting.

The steps to properly use a thermal laminator to protect printed images are as follows:

1.Completely dry: Ensure the printed image is completely dry to avoid poor lamination due to undried ink.

2.Keep clean: Clean the infeed and outfeed areas of the laminator to ensure there is no dust or debris.

3.Choose the right film: Choose glossy or matte film as needed. Glossy is suitable for brightly colored images, while matt is suitable for preventing reflections.

4.Parameter setting: Adjust the temperature and pressure of the laminator. Usually, the temperature is set between 100°C and 120°C. Adjust the feed speed according to the thickness and type of film.

Notes

1.For some heat-sensitive materials, heat treatment can be performed before lamination to activate the viscosity of the material to ensure the best lamination effect.

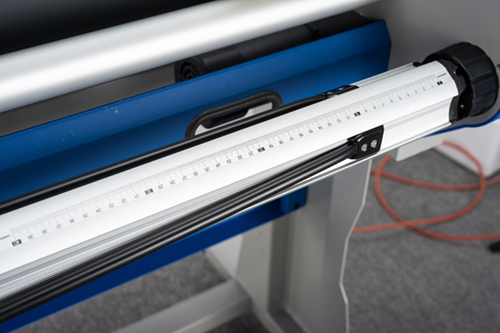

2.Before selecting a laminating machine, it should be noted that the width of the selected film should match the maximum width of the laminating machine to avoid incomplete coverage during the laminating process.

3.When selecting a laminating film, the environmental performance of some products can be considered. Choosing an environmentally friendly film for lamination can effectively implement the ecological concept of sustainable development.