In all areas of modern industrial production, precise positioning, and efficient operation have become the key to improving productivity and product quality. The application of laser technology in industry is extremely wide and deep, covering almost every aspect of manufacturing.

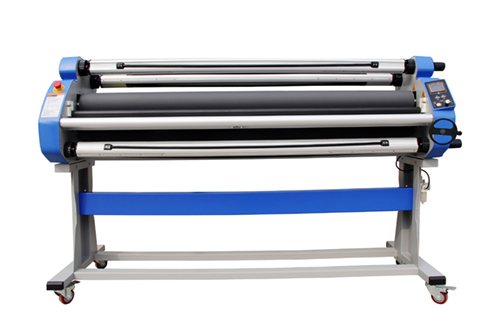

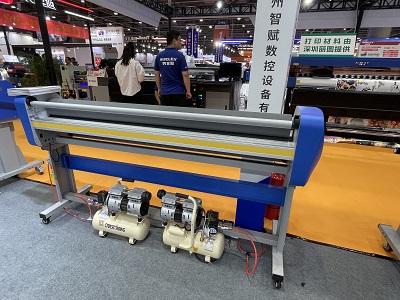

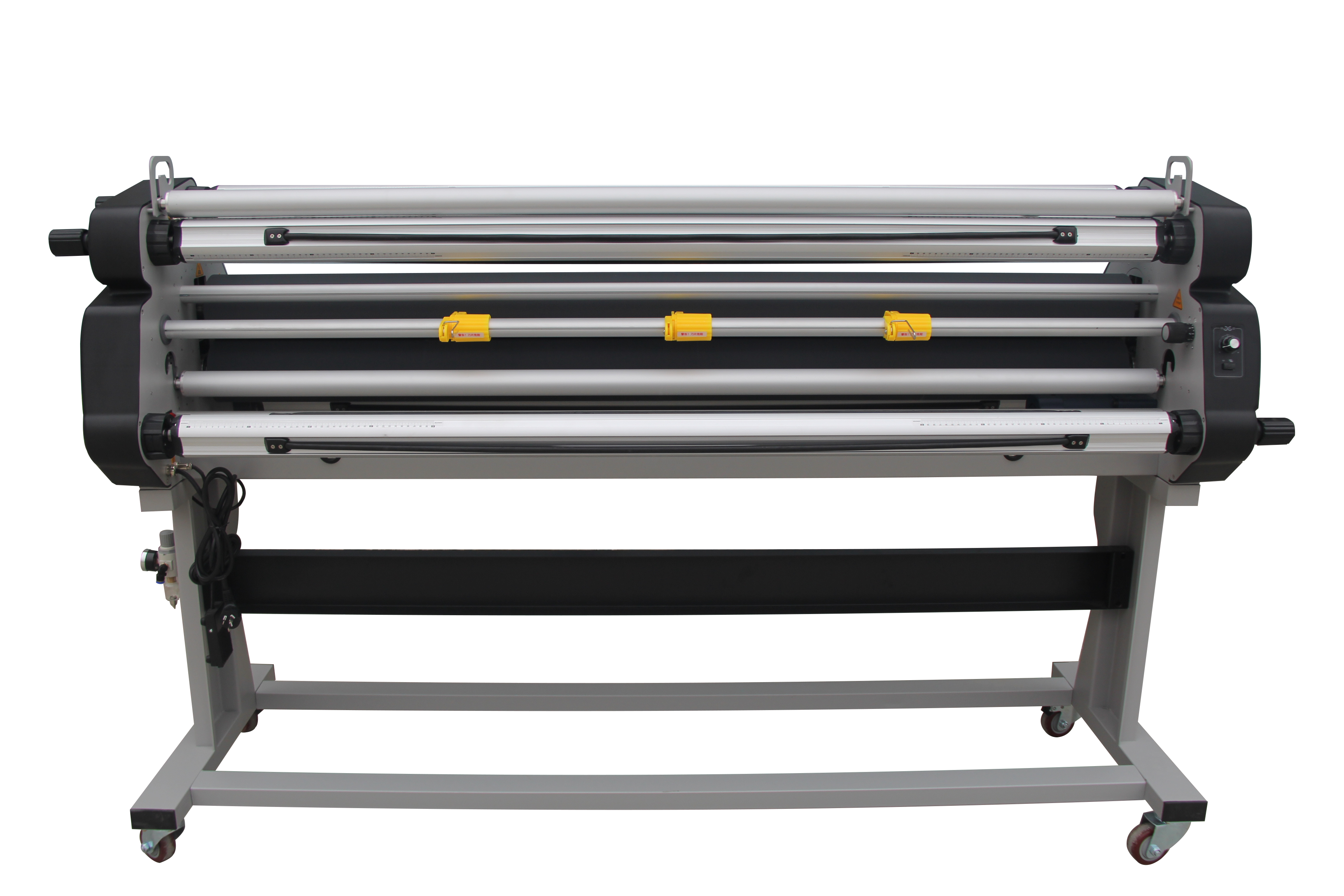

MEFU’s industrial laminators have upgraded their laminate cutting systems, combining laser positioning and vertical cutting to provide users with the perfect laminating and cutting solution.

Technical parameters of the MF1700-F3

•Full-featured SMART PRO system: laminating statistics, height and pressure adjustment, overload alarm device.

•Cutting method: laser tracking vertical cutting

•Working speed: up to 50 m / min.

•Maximum lamination width: 1630mm

•Maximum lamination thickness: 28mm

•Heating method: Top heating

![]()

Advantages of laser positioning applied in laminating cutting:

1.High accuracy: laser positioning can provide very high positioning accuracy, usually at the millimeter level.

2.High efficiency: Laser positioning enables fast positioning speeds, thus enabling real-time access to target position information.

3.Automation: Automatic checking and marking of the positioning cutting position reduces manual intervention and improves operational safety.

4.Non-contact: Laser positioning is a non-contact measurement method that does not require physical contact with the target, thus avoiding damage or interference with the target.