Laminating machine hobby lobby

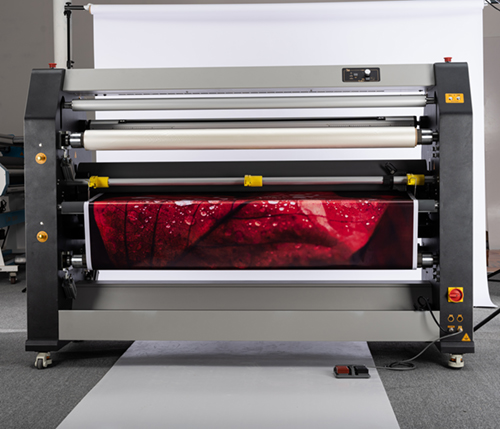

How to use laminating machine hobby lobby, suitable for home depot etc indoor use, a good helper for expand your business, capable of heavy-duty roll-to-roll operation with multi-functions. This PREMIUM equipment can meet most applications, ideal for all inkjet and printing materials.

Laminating Machine Recommendations

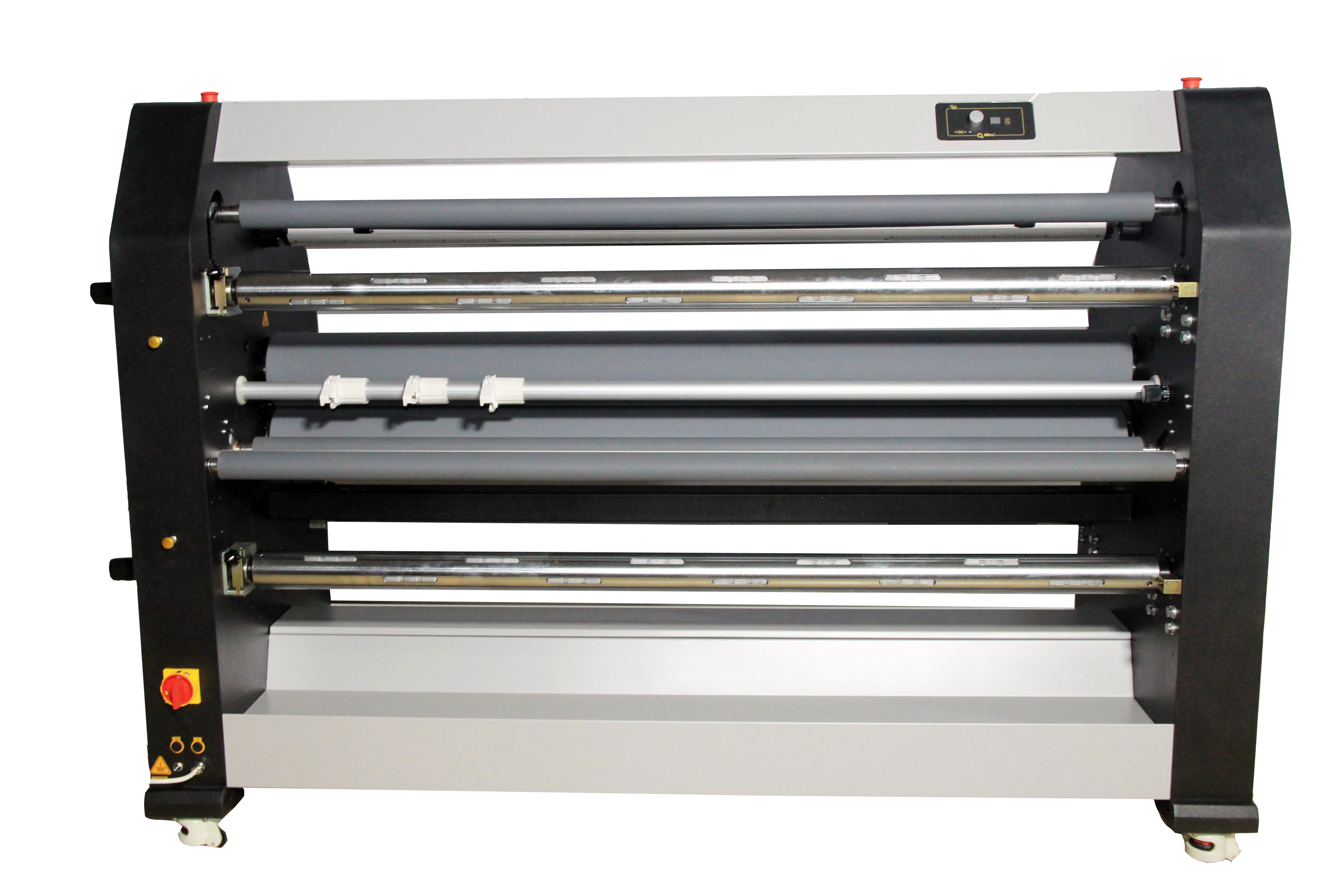

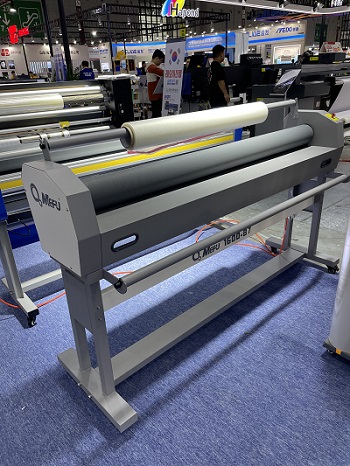

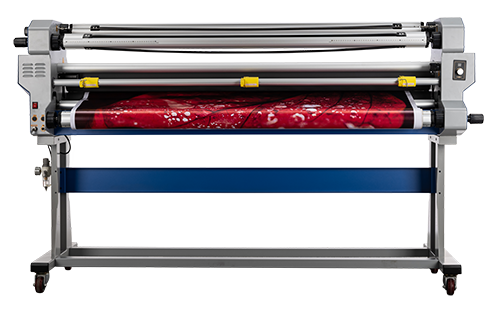

One of the best sellers MF1700-M5 has a lamination width of up to 1.63m/64’’, this size laminator covers the most common finishing requirements with high-quality results. Premium silicon rollers ensure the life of the machine and are trouble-free. The unique anti-tilt and anti-fold system ensures clear output. Its simple design makes it extremely easy to use and provides high-quality laminating results.

Specification

| Smart System | None | Up and down | Hand Crank | |

| Control Panel | Front | Roller | Silicon | |

| Max Lam Width | 1630mm/64” | Roller Diameter | 130mm | |

| Max Lam Thickness | 23mm/0.9” | Trimmer Holder | None | |

| Max Speed | 12m/min | Power | 1600W | |

| Heating | Top Heated | N.W. | 200KGS | |

| Max Temp | 60 degrees | Dimension (LWH) | 2200x790x730mm |

Characterization

1. Smart Entry System

It is easy to check speed, temperature, and Lamination statistics.

2. Auto-locked exchangeable shaft

Upgraded shaft caps and holders can be easily locked and loaded media. Anti-static string.

3. Precise vertical cutters

Fully adjust the position, its tungsten blades have a lifetime of over 15000m.

4. Rear control panel

Easier for speed adjustment and cutter activity.

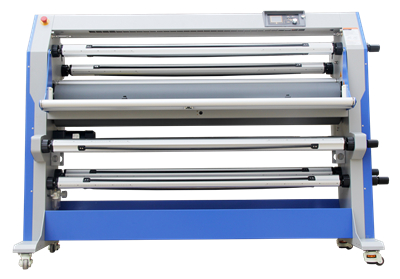

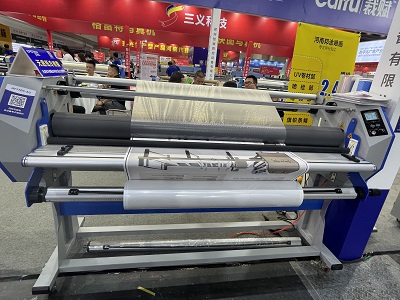

The MF1700-M1 PLUS roll laminator is equipped with a pneumatic lift system. This entry-level series laminator is designed with an ABS cover to make the machine more durable and aesthetically pleasing. Despite its low profile, it is capable of handling a wide range of intense workloads. The MF1700-M1 PLUS goes far beyond the basic needs of a print finishing solution.

Specification

| Smart System | Entry | Up and down | Pneumatic | |

| Control Panel | Front and Rear | Roller | Silicon | |

| Max Lam Width | 1630mm/64” | Roller Diameter | 120mm | |

| Max Lam Thickness | 28mm/1.1” | Trimmer Holder | Optinoal | |

| Max Speed | 9m/min | Power | 1600W | |

| Heating | Top Heated | N.W. | 150KGS | |

| Max Temp | 60 degrees | Dimension (LWH) | 2260x860x750mm |

Characterization

1.Smart Entry System

The newly designed control panel allows the user to easily monitor the machine’s operating status, including speed and temperature, to ensure optimal laminating results during operation.

2.Anti-static string

Anti-static string is an efficient way to ease static. It can effectively prevent static build-up through the design of special materials, thus enhancing operation safety and work efficiency.

3.Optional safety vertical cutting

The optional safety vertical cutting feature makes the machine safer and more efficient when handling materials. The diversified configurations of two single-edged blades and a double-edged central blade enhance cutting flexibility and efficiency and can meet different cutting needs.

4.Top Heating

Low-temperature cold laminating allows for better lamination between the film and the material, enhancing the laminating effect.

Notice

1. Slowly run the machine when heated.

2. Lift the roller after finishing the lamination.

3. Keep rollers clear.

4. Do not scratch the rollers.

5. Lubricate the gears and chains.

6. Friction mats should be checked and replaced regularly.

MEFU provides professional technical training and complete after-sales service to every customer who purchases a machine. Feel free to contact us with any questions about laminating!

FAQ

Difference Between Hot and Cold Laminating Film-Which is better?

Cold laminated and hot laminated films are widely used in the market, and there is no distinction between good and bad. When choosing, we only need to choose the one that is more suitable for ourselves according to our own needs.

What Happens If You Laminate Photos?

The photo lamination process is to press a transparent film on the surface after printing the product. After lamination, the surface of the photo is smooth, which can prolong the preservation life of the photo.

Laminating Reduces Print Quality?

We can not generalize about the good and bad of the print laminating, laminating is a complex process that requires specialized technology, laminating damage to the print quality may be due to inexperience in laminating, not laminating will necessarily damage the print quality. So the impact of laminating on print quality is complex, both positive and potentially negative impact.