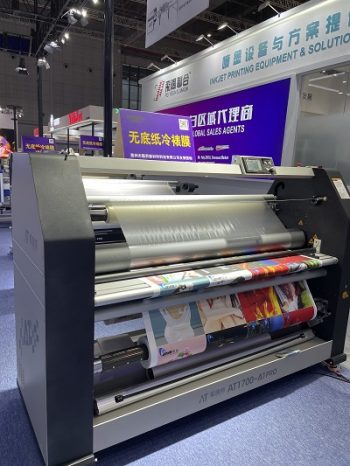

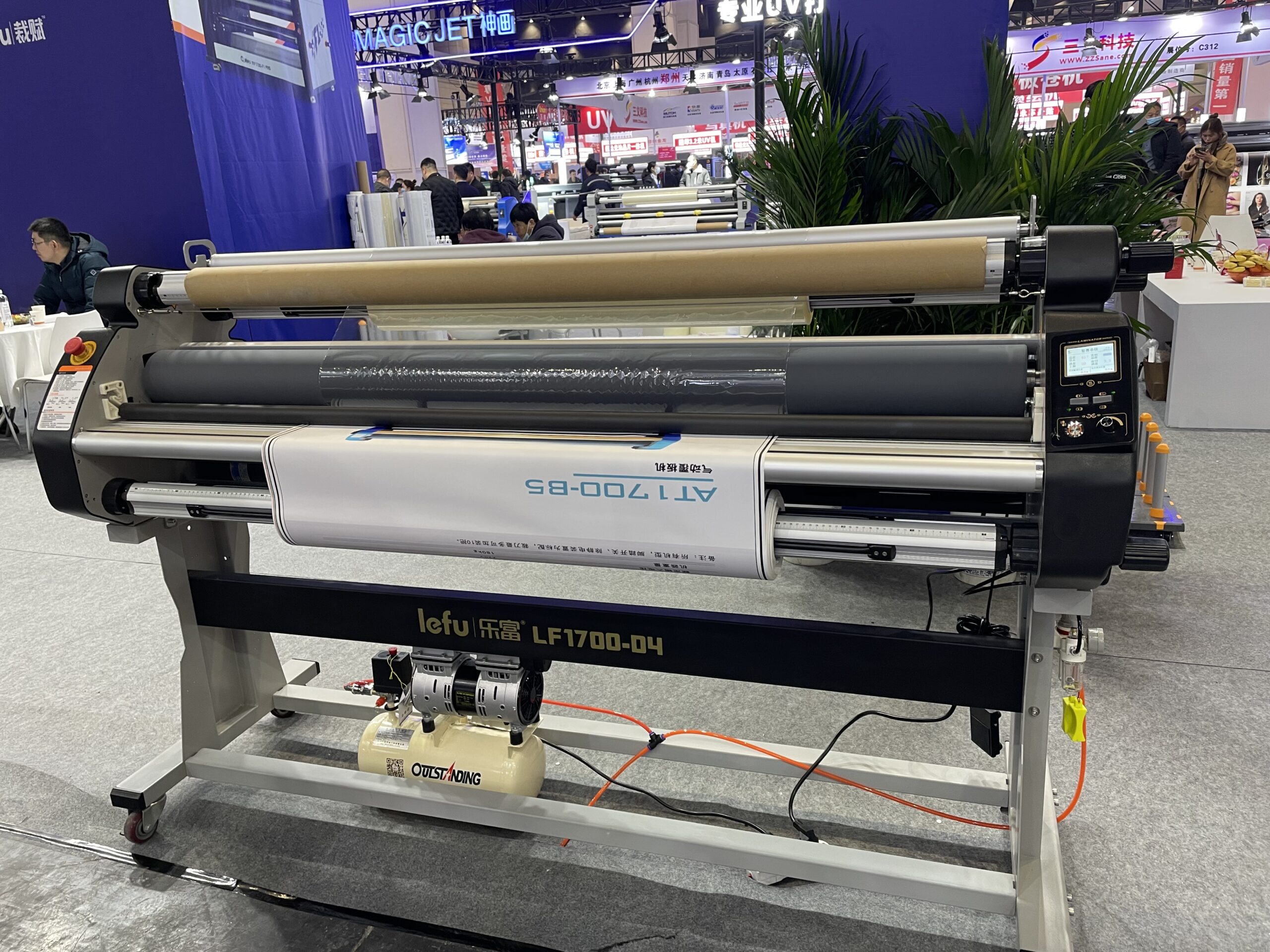

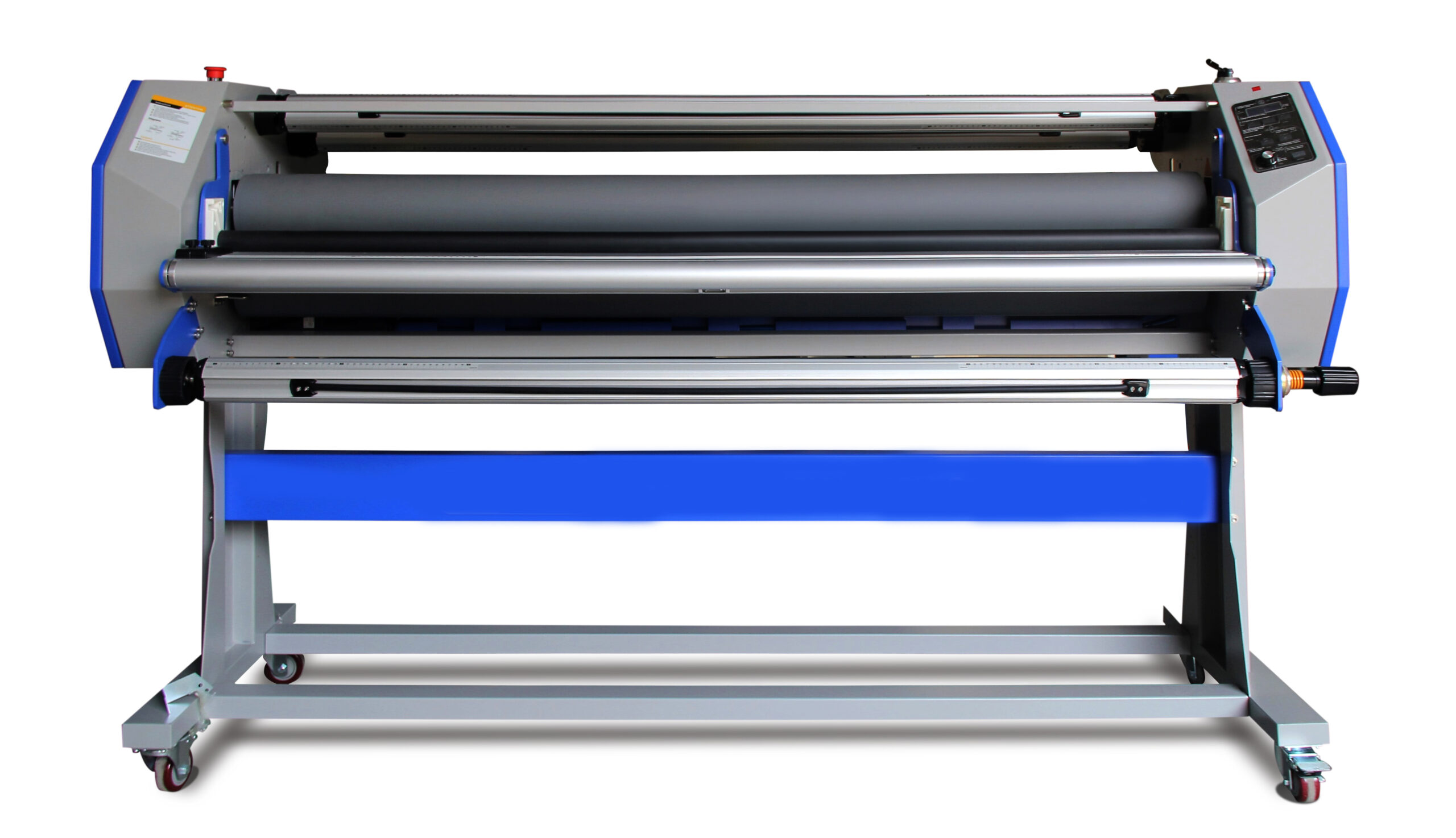

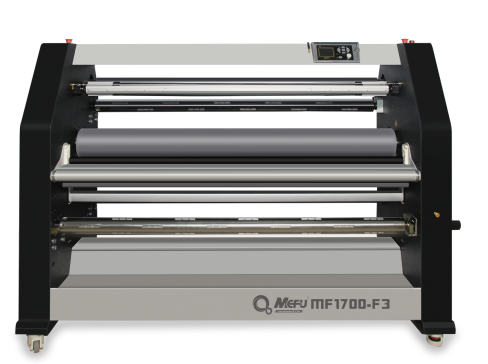

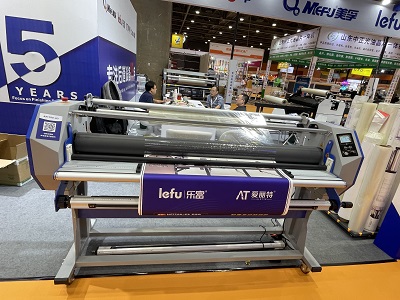

Lefu Dual-heated laminator with cutter LF1700-D2

The industrial laminator LF1700-D2 combines innovation, versatility and power with little costs of investement and a range of options and a kit for roll-to-roll processing. Thereby it allows you to offer a broad spectrum of services and applications, from car foiling, packaging manufacturing, displays and sign-making to interior design and outdoor adverts. The pneumatic system reduces set-up times and is very easy to use. The pneumatic pressure system also provides a steady level of pressure over the whole length resulting in the material being transported through the machine absolutely straight and without wrinkles, even with extra-large formats or when working from roll-to-roll.

The Dual-heated rollers with max temperature of 120C offers the possibility not only for laminating but also for mounting and encapsulating up to 1630mm. Additionally, its fully adjustable tungsten blades can cut most materials with a lifetime that over 15000m.

LF1700-D2 is a laminating unit that combines innovation, performance, low investment level, full upgradability and protection of the investiment in the long term. The industrial laminator is in fact designed and built to fit the widest range of applications, from car wrapping to interior decoration and corrugated packaging, up to a wide range of display graphics and sign-making applications.

Thanks to its pneumatic technology, LF1700-D2 reduces the setup time of the machine and the need to employ specialized personnel. The availability of a version with heated rollers further increases the fields of use.

KEY FEATURE

Plug & Play: More friendly for assemble. Strong and integrated frame, easy to use. It’s enough to plug it in, bring the laminator up to temperature and start working

Smart Entry System: Speed, temp, and lamination statistics, easy to check figures of set temp, real temp, and button speed, as well as find your lamination records in 30 days

Self-adaptive: the air pressure system with independent pistons automatically adjusts to different thicknesses and the manages the flatness defects of the substrate. The rollers get adapted to the surface in real time

Flexible: it’s possible to pre-set the pressure applied to each substrate. Once the material is placed is always possible to make adjustments to the pressure

|

Pro Series |

LF1700-D2 |

|

Smart System |

ENTRY (Option for PRO) |

| Front Panel |

Speed and temperature |

|

Rear Panel |

Speed |

|

Lamination Statistics |

Yes |

|

Foot Pedal |

Single foot pedal |

| Max Lam Width |

1630mm/64” |

| Max Lam Thickness |

28mm/1.1” |

|

Max Speed |

20m/min |

|

Heating |

Dual or Top Heated |

| Max Temp |

120°C or 60°C |

|

Up and Down |

Pneumatic |

| Roller |

Silicon(130mm) |

|

Trimmer Holder |

2 Single and 1 Double Central blades |

| Power Input |

5200W/2800W/1600W |

| N.W. |

260KGS |

More info pls contact to cindy@mefu.cn