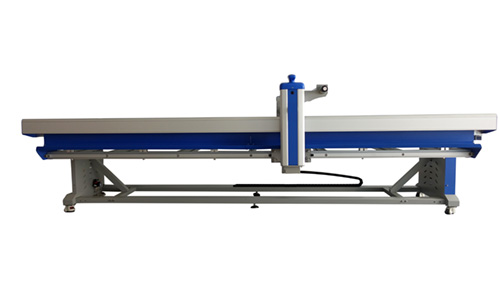

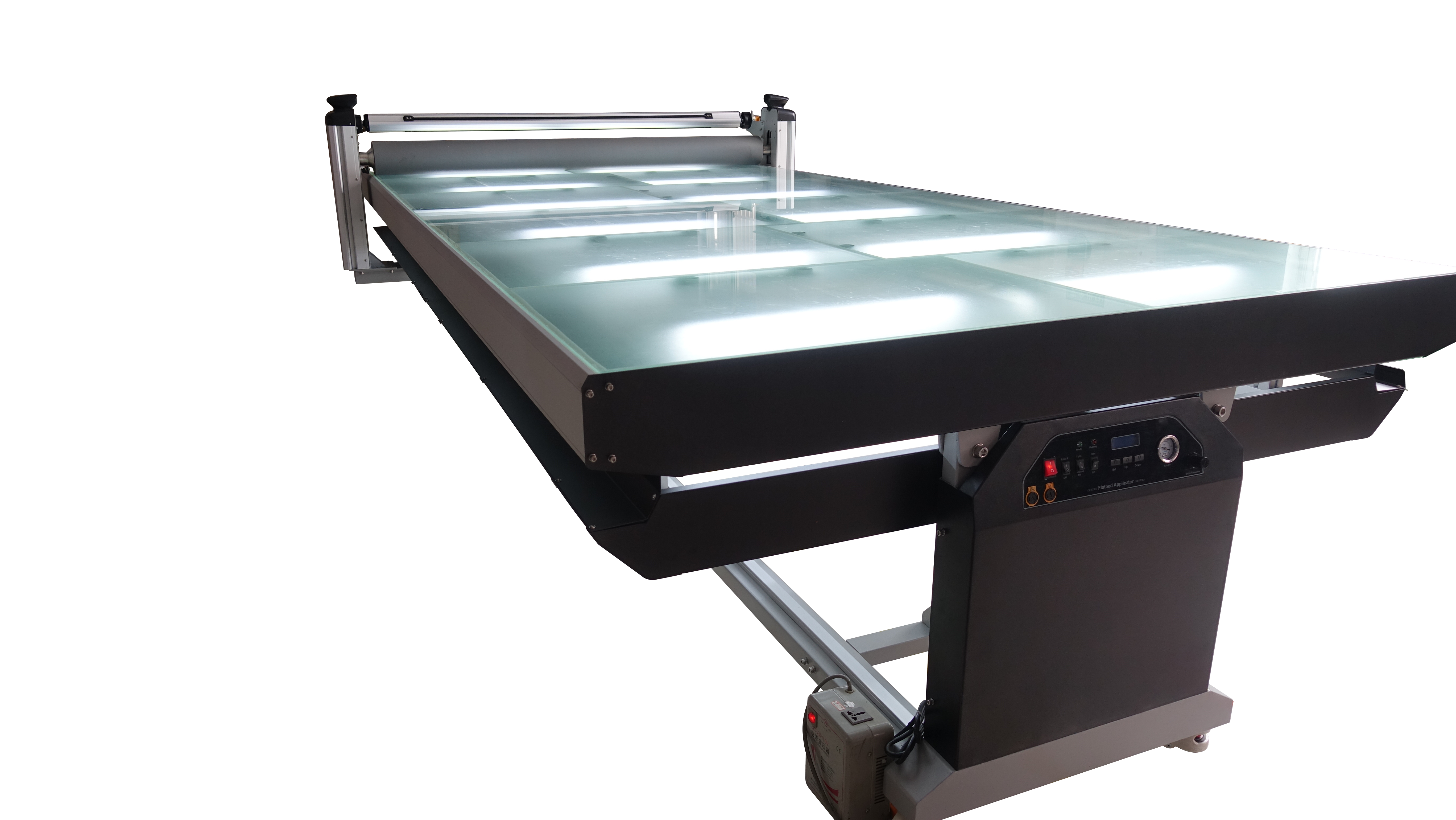

Optional heated rolls roller table price

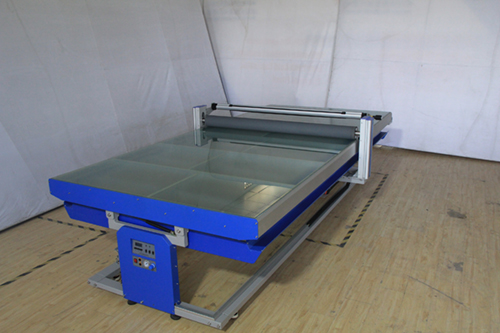

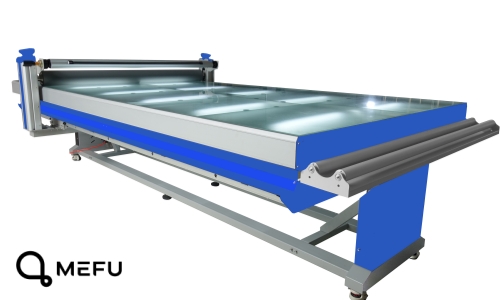

The flatbed applicator B4 series is the fully equipped multipurpose machine that gives you access to the superior production method provided.

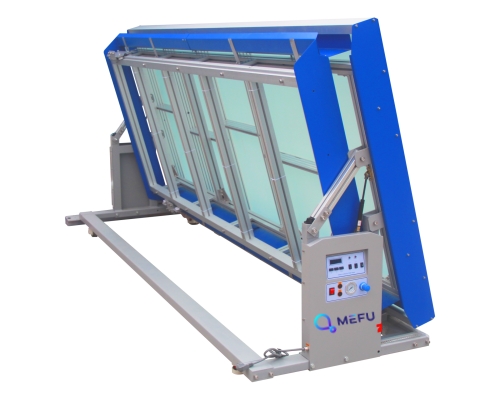

It’s unique tilted table can reduce the delivery cost and more easier to entry the facility. Fast assembling and easy operating.

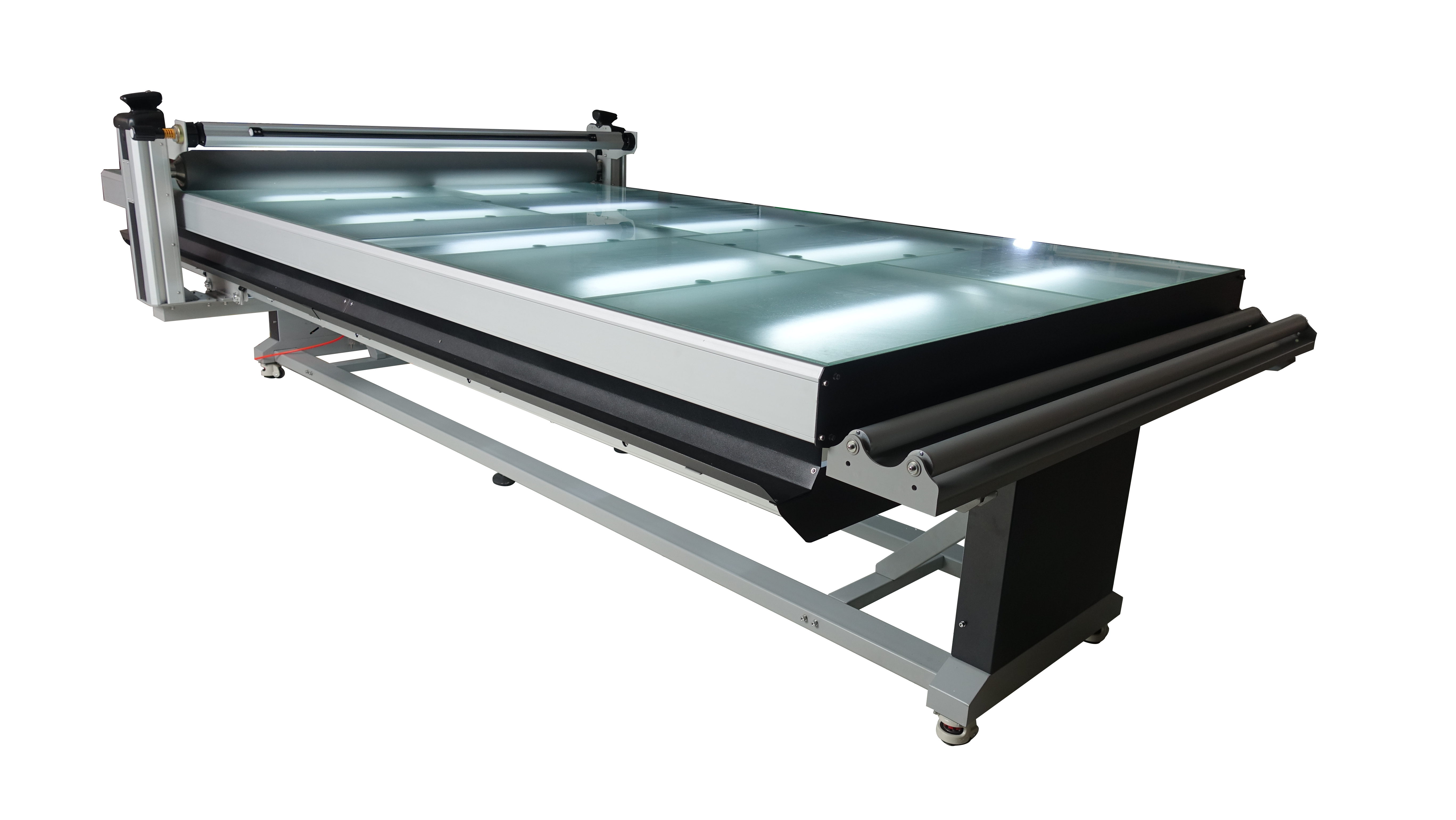

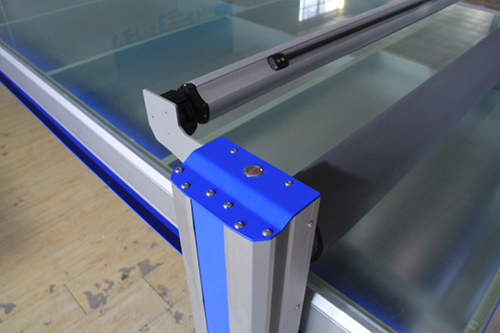

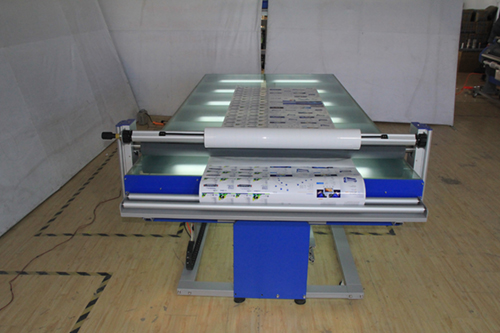

A media roll holder at the end of table provide easy material feeding possibility.

The flatbed applicator B4 series is a fully equipped multipurpose machine that gives you access to the superior production method provided.

Its unique tilted table can reduce the delivery cost and more easier to enter the facility. Fast assembling and easy operating. A media roll holder at the end of the table provides an easy material feeding possibility.

In addition to these significant advantages, the optional heated rolls roller table adds more highlights to this machine.

1. Improve the quality of lamination: Heated rollers can provide extra heat during the lamination process, which helps the glue and film bond better, and this improves the quality of the printed material.

2. Wide range of applications: Heated rollers allow the machine to handle different types of materials, including flexible and rigid substrates that require heat treatment, making the equipment more versatile.

3. Precise temperature control: Heated rollers are usually equipped with a temperature control system that can precisely regulate the temperature to meet the needs of different materials and processes, ensuring consistent laminating results.

The optional heated rolls roller table not only enhances the functionality and flexibility of the roll laminator but also improves production efficiency and product quality, making it an important component of the MEFU flatbed laminating machine.

FAQ

1. In addition to the heated rolls roller table, what other equipment also affects the production efficiency of flatbed lamination?

Pneumatic lifting systems, cutting devices, control panels, material reels and trays, and automation functions.

2 What are the common optimization measures and techniques for the key equipment influencing the productivity of flatbed laminating?

Optimization of pressure regulation, the addition of adjustable cutting knives, double rollers design, Addition of automatic feeding systems, regular maintenance and servicing.