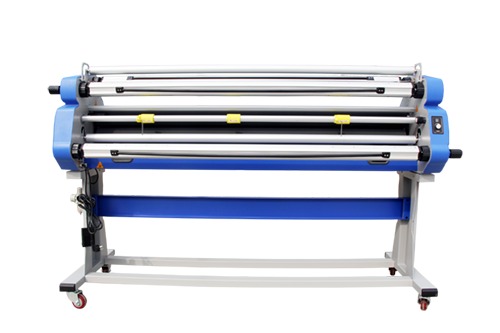

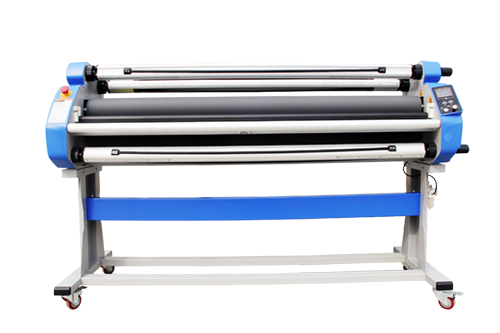

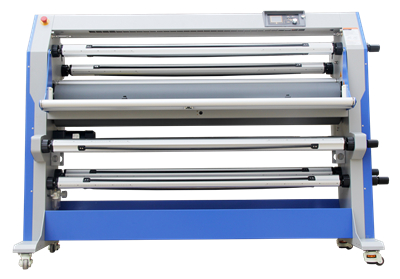

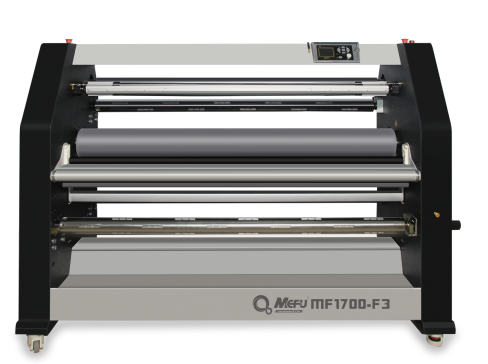

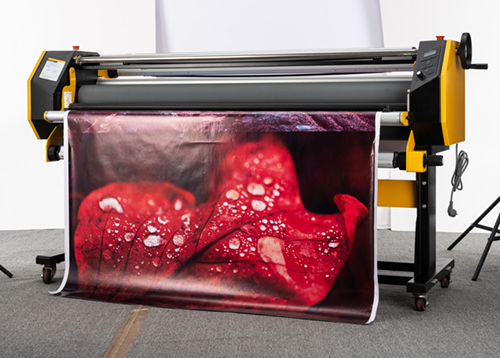

Wide Format Heat Assist Roll Laminator With Pneumatic Lifting System

MEFU pneumatic lifting laminating machine adopts pneumatic pressure as the power source, through the pneumatic transmission system to control the lifting, it has the advantages of energy saving, safety, environmental protection, mute, etc., and is suitable for paper, posters, and other materials laminating.

Wide Format Heat Assist Roll Laminator Features:

1、Adopting pneumatic lifting system, smooth lifting, balanced pressure, good laminating effect.

2、 High-quality silicon rollers, the rubber surface is flat, with no deformation, temperature resistance of more than 100 ° C, and an outer diameter of 130 mm.

3、Silicon roller heating temperature up to 120°C, temperature control system to control the temperature accurately.

5、Adjustable tensioning system improves the film ductility and effectively avoids wrinkles.

6、Turnable aluminum alloy worktable, convenient for machine maintenance.

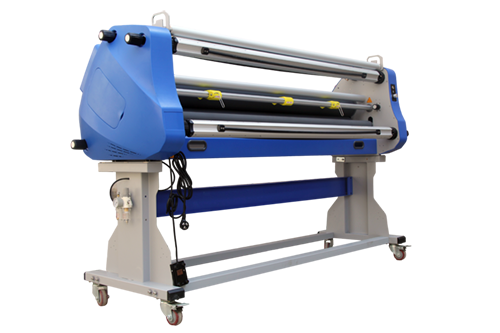

Laminating machine pneumatic lifting and electric lifting difference

MEFU pneumatic lifting laminating machine adopts pneumatic pressure as the power source, through the pneumatic transmission system to control the lifting, it has the advantages of energy saving, safety, environmental protection, mute, etc., and is suitable for paper, posters, and other materials laminating.

The electric lifting laminator adopts an electric motor as the power source, which has the advantages of fast lifting speed, high precision, good stability, etc. It is suitable for the laminating of large and heavy materials.

In addition to the difference between electric and pneumatic lifting and lifting, many people have concerns about cold laminating and hot laminating what is the gap? What will be the effect of hot laminating?

Cold lamination utilizes the upper and lower two silicon rollers to pressurize the sticky PVC film directly on the material to be laminated. Hot laminating works in addition to the use of pressure, the most important thing is to be equipped with high-quality silicon rollers that can be heated. The lamination is carried out by the double action of heating and pressure.